The 21st century is a century of advanced science and technology, and an important century for industrial breakthroughs. Since entering the 21st century, we have continuously developed and improved numerical control equipment, including CNC machine tools, which have an important position in the industrial field. Modernization focuses on digital construction, which also accords with the development of numerical control technology, and provides powerful help for the rapid development of numerical control technology.

The first is the application of the Internet of Things technology. At present, China's machine tool industry has just made a breakthrough on the road of numerical control. However, to further improve efficiency and reduce costs, the Internet of Things technology is needed. The use of the Internet of Things technology will bring the possibility of overtaking in China's machine tool industry, but it should be noted that the Internet of Things technology requires high-end machine tools based on "high precision, high efficiency, and high functionality." Even if ordinary machine tools use the Internet of Things technology, it still has little significance for improving quality and efficiency.

The second is automated production. At present, the level of development of China's manufacturing industry is difficult to build a smart factory on a large scale, but it is still possible to use some automated equipment. Therefore, China's machine tool companies need to improve their ability to adapt to automated production, on the one hand, increase the use of automation equipment in their own production. On the other hand, it is necessary to strengthen the ability of machine tools to cooperate with robots and other automation equipment to provide downstream companies with richer automation solutions.

The latter is intelligent, and there are many intelligent machine tool performances, such as the use of process software, the ability to communicate with people, the ability to process navigation, the perception and compensation of the working environment, intelligent maintenance, and so on. The more intelligent the machine tool is, the simpler the production process will be, which is also the development trend of all manufacturing industries.

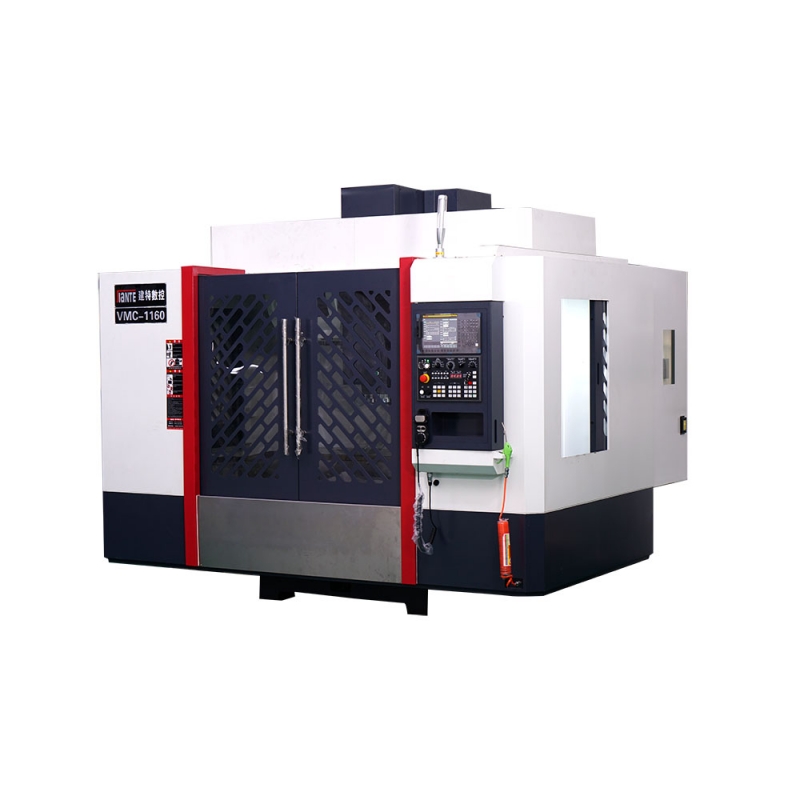

Manufacturers of CNC vertical machining centers have a lot of room for improvement in high-precision development. Although the current CNC parts machining centers have attached great importance to accuracy issues, scientific and technological personnel have found that their accuracy can be further improved. On the other hand, we are constantly looking for more suitable ways to improve the internal structure and working principle of the machine and make it more perfect.

In recent years, China's manufacturing industry has developed strongly, especially the rise of new fields represented by electric vehicles, which has brought opportunities for the development of China's CNC parts processing center industry. But we also need to pay attention to the fact that the production of new technologies has also put forward higher requirements on the performance of CNC part machining centers. The development of CNC parts processing centers towards network and intelligence is essentially to adapt to new production requirements.

QQ:380598058

Cell/Whatsppp:+8618948856139

Email:julie.cnc688@gmail.com

address:No. 10, Industrial Avenue Middle,

Xiaolan Town, Zhongshan City (Building A)